PAA ANODES BONDING

PAA is a versatile binder for Si anodes, with performance highly dependent on pH and Li+ content. Optimized formulations (e.g., LiOH-PAA at pH 4.5 or dopamine-grafted PAA) significantly enhance cycle life and capacity retention. However, challenges remain in thick electrodes and electrolyte compatibility.

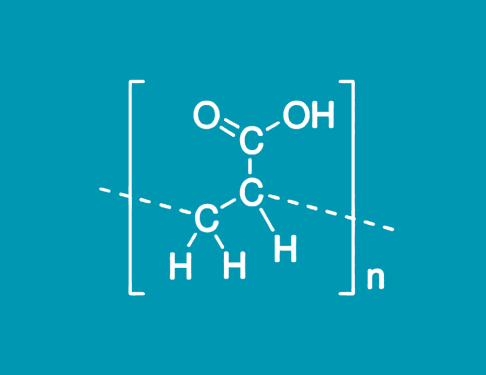

PAA as a Binder for Silicon Anodes

Silicon anodes suffer from significant volume expansion (~400%) during lithiation/delithiation, leading to electrode degradation. PAA-based binders help mitigate this issue by:

Enhancing Adhesion: PAA forms strong hydrogen bonds with Si particles and the current collector, improving mechanical integrity.

Self-Healing Properties: Modified PAA with boronic ester and dopamine (xPAA-B-DA) exhibits reversible bonding, enabling structural recovery after cycling.

Electrochemical Performance: Si anodes with xPAA-B-DA retain 53.7% capacity after 350 cycles at 0.5C and 63% after 200 cycles at 1C.

PREPARATION METHOD

Preparation method: The preparation methods of Acrylic acid Polymers mainly include free radical polymerization and ionic polymerization. In the free radical polymerization method, acrylic acid and acrylate monomers form a resin by free radical polymerization; in the ion polymerization method, acrylic acid reacts with an initiator such as butyl lithium to generate a lithium acrylate, and then reacts by adding an active monomer to form a Acrylic acid Polymers.

Key Modifications and Enhancements

To optimize PAA's performance, researchers have developed several strategies:

Lithiation (PAALi): Adding LiOH improves ionic conductivity and stabilizes the solid-electrolyte interphase (SEI)

Cross-Linking: Dopamine-grafted PAA (xPAA-B-DA) forms dynamic boronic ester bonds, enabling self-repair and capacity retention (53.7% after 350 cycles) .

Hybrid Networks: Combining PAA with polyampholyte hydrogels (ionic/metal-ligand bonds) enhances mechanical strength and ionic conductivity for strain-sensitive applications

PROCESS

The key to the PAA production process lies in the precise control of the polymerization reaction and subsequent processing. Raw material preparation affects the purity of the final product;

polymerization reaction,

the temperature and initiator dosage determine the molecular weight and viscosity;

purification and concentration ensure product purity;

formulation and adjustment regulate performance to meet application requirements.

Drying and post-processing affect transportation and storage methods;

quality testing ensures that products meet standards. Precise control of each step affects the bonding of PAA strength, chemical stability and adaptability.

PROCESS FLOW

FEATURES

Silicon (Si) -based materials have been identified as a potential alternative anode owing to their superior theoretical capacity compared to conventional graphitic carbon.

EQUIPMENT SUPPLY

DOWNLOADS

Add paragraph text. Click “Edit Text” to update the font, size and more. To change and reuse text themes, go to Site Styles.

UREA TO AMMOUNIA

.png)

Add paragraph text. Click “Edit Text” to update the font, size and more. To change and reuse text themes, go to Site Styles.

WFF EVAPORATOR

.png)

Add paragraph text. Click “Edit Text” to update the font, size and more. To change and reuse text themes, go to Site Styles.