WORKING PRINCIPLE

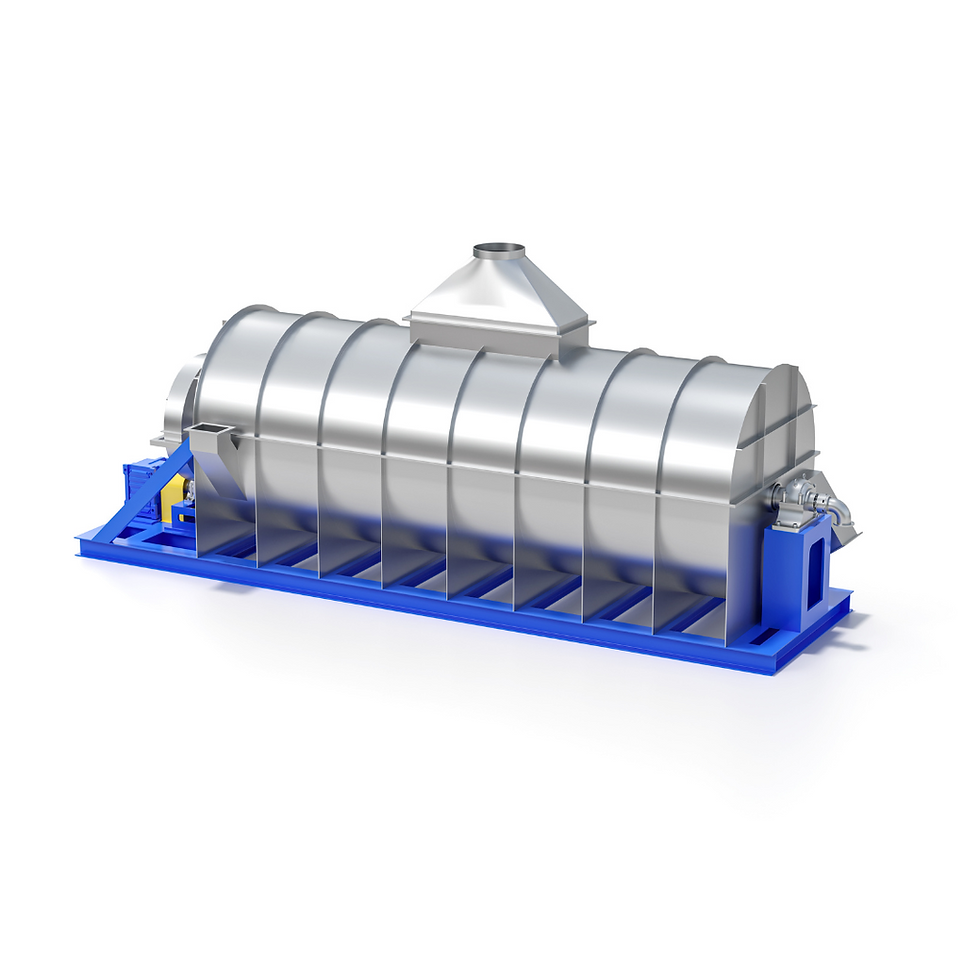

The steam heated tube bundle slowly rotates in a fixed housing and conveys the product to be dried axially through the dryer. Shovels transport the product along the circumference of the housing, where it falls through the heated tube bundle for each rotation.

The economic and gentle drying is achieved by contact with the tubes and convection. The heat source is typically saturated steam between 4 – 10 barg, solutions with lower steam pressure are available.

.png)

MAIN DESIGN FEATURES

Effective self-cleaning to minimize dead zones, product accumulation and product degradation

Excellent kneading and mixing for better homogenization

Effective heat transfer

High surface renewal efficiency

Large free vapor volume

Precise and uniform temperature control due to large heat transfer areas

Continuous or batch processing

Process intensification

Processing of sticky and highly viscous products

Residence time is independent from agitator speed, wide and flexible range of average residence times

Reliable process scale-up from pilot to industrial units

Large production capacities, economy of scale

Maximum process yield per unit volume

Reliable, robust design

Short return of investment

.png)

BENEFITS

Drying only with indirect steam and sweep ambient air, means no pollution to your product.

Low installation costs through modular design and pre-manufacturing.

Gentle drying through low temperatures.

Low energy consumption in the range of 1,25 to 1.3 lbs of steam/lbs of water evaporation.

Optimal sealing and insulation secure high wet-bulb temperatures and optimize energy recovery up to 67% in further processes (e.g. evaporator).

Safe process: minimized oxygen content ensures the lowest explosion and fire risk. ATEX design if required.

Clean and environmentally friendly: Integrated dust collector to minimize dust emissions to the atmosphere – closed-loop systems are also available.

Closed gas-tight system as well as design for drying below atmospheric pressure are possible.

APPLICATIONS

Starch and Grain Industry

Alcohol / Ethanol and Brewery

Energy & Environmental

MODELS AND TECHNICAL SPECIFICATIONS

Model | Area (m²) | Drying Capacity (kg H2O/m² h) | Rotate Speed (r/min) | Power (Kw) | Dimensions (mm) |

TBD0400 | 400 | 2.5~4.5 | 7~11 | 30 | 10780*2700*850 |

TBD0500 | 500 | 2.5~4.5 | 7~11 | 37 | 10900*2810*4110 |

TBD0600 | 600 | 2.5~4.5 | 7~11 | 45 | 11030*3030*4270 |

TBD0700 | 700 | 2.5~4.5 | 7~11 | 55 | 11170*3260*3875 |

TBD0800 | 800 | 2.5~4.5 | 7~11 | 75 | 11440*3470*4100 |

TBD1000 | 1000 | 2.5~4.5 | 7~11 | 90 | 12200*3660*4310 |

TBD1200 | 1200 | 2.5~4.5 | 7~11 | 110 | 12280*3980*4730 |

TBD1300 | 1300 | 2.5~4.5 | 7~11 | 132 | 12900*4160*4900 |

TBD1500 | 1500 | 2.5~4.5 | 7~11 | 132 | 14000*4600*5400 |

TBD1600 | 1600 | 2.5~4.5 | 7~11 | 160 | 14500*5000*5900 |

APPLICATION FIELDS

DOWNLOADS

DOWNLOADS

ENGLISH

ENGLISH

.png)

A coil-wound heat exchanger (CWHE) consists of one or more spirally wound tubes...

COIL-WOUND HEAT EXCHANGER

.png)

The Disc dryer efficiently dries liquid products containing solids in suspension...

DISC DRYER

.png)

The forced circulation evaporator uses a pump to circulate liquid through steam-...

FORCED CIRCUL. EVAPORATOR

.png)

A wiped film evaporator (WFE), is used ot separate and concentrate compone...

WFF EVAPORATOR

.png)

Continuous scraped surface crystallizer is generally used in cooling crystalliza...

TUBE CRYSTALLIZER

.png)

Steam Tube Dryer (STD) is an indirect heat dryer using steam tubes heated by ste...

STEAM TUBE DRYER

.png)

DTB crystallizer is for the production of large-size crystalline materials...

DTB CRYSTALLIZER